Intro Slave Box 2 wiring

The owner of the house lost the remote controllers which was paired to the opener throughout the years. Now it seems he cannot by these old controllers anymore so he had two options. Buy a new opener which would be very costly or find a solution to use newer remote controllers. Obviously we went to implement the second option. This is now we arrived at today’s topic which is Slave Box 2 external radio board wiring to Exitec garage opener.

Investigation

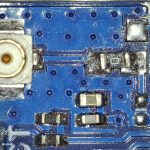

When we opened the main unit of the garage opener we realized there is no exact ports, connections or other possibilities to hook on. The Slave box 2 requires input power to work and it has 2 NO/NC connector to use. This is what we needed to combine somehow to make our customer happy. Of course all the time when we need to do something like this we are very carefully measuring all ports, connectors voltages and write them down.

Solution Slave Box 2 wiring

After the initial investigation we tried to find relevant wiring and installation how to manuals. After several hours of searching without luck it turned out that there is no information available online. Right here would like to say “Thank you!” to all the installers whom we were able to reach as they were so kind and helped us with their expertise. So the solution is the following:

- keep all the hooks/loops as if you remove them the gate will not work.

- you can safely get the power from the infra port

- you can use the gate port ground leg to have a signal which can be “transmitted” via the Slave Box 2 relay legs.

- you need yo use proper wire size as the ports are not designed to handle thick wires.