Solar street light repair intro

We bought a two new solar street light which we planned to mount on the street front of our property. After reading the manual it recommended to put it to direct sunlight for a day or two to make sure the battery will be charged. Unfortunately the batteries fried themself and we had no lights anymore this is where our solar street light repair story begins.

Investigation

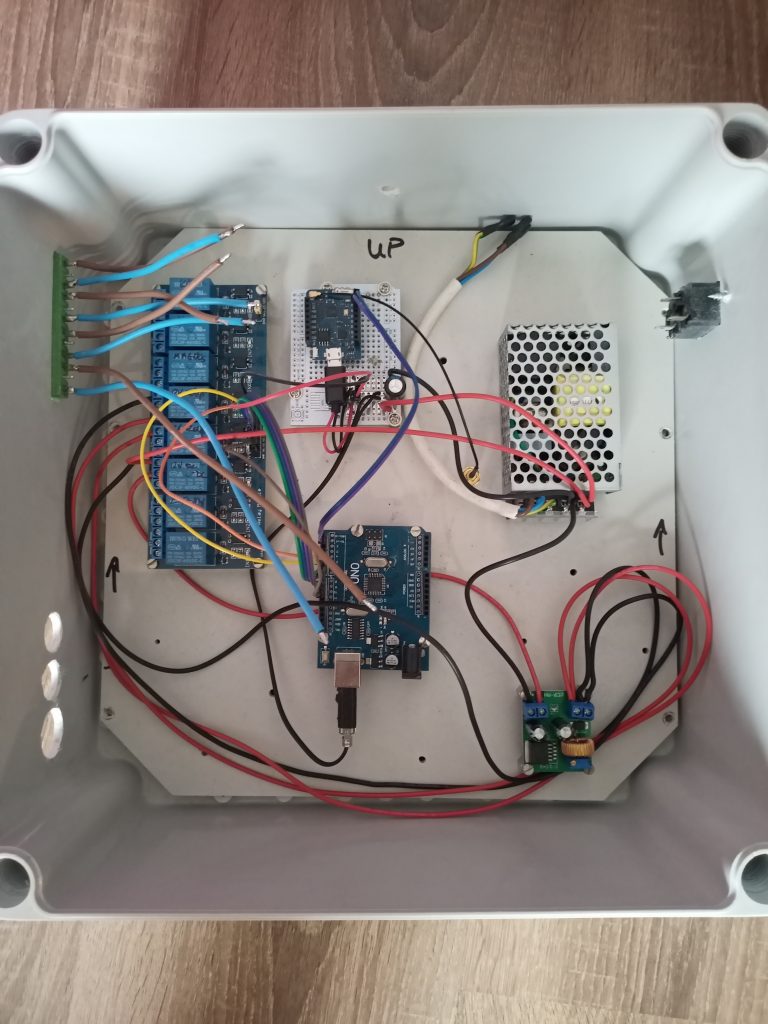

After disassembling the unit it revealed its secret. The LiFePO4 battery “ran out” of juice literally and now it was showing short using a multi-meter. As we have lots of space in the lamp we decided to create a new battery set from our remaining 18650 cells.Solution

We took our remaining cells and created a super huge capacity battery so our solar street light can light all now long even during the long winter nights. We created a 2S Li-Ion battery pack using BMS to make sure we will not over or undercharge the cells. We had this idea after we have measured the short voltage value of the solar cells. This was a mistake! The solar cells produce less voltage when they are under load… So after we created our battery pack we faced two issues: – we created a bigger pack and it did not fit [we forgot to calculate the size of the plastic holder] – the battery pack provided more voltage then the circuit was needed. Yes your are right we fried the PCB! 🙁Solar street light repair tests results and future improvements

We have the following open topic:

– when disassembling something do not through away parts till you took photo of them. Even if they are leaking batteries

– when disassembling something do not through away parts till you took photo of them. Even if they are leaking batteries

– do some test with labor power supply unit to make sure about the operation voltage of the system

– the lamps do not work

– we do not have a proper battery

– we do not have a proper battery

– do not be afraid to use Google

– we did not solve the issue 🙂